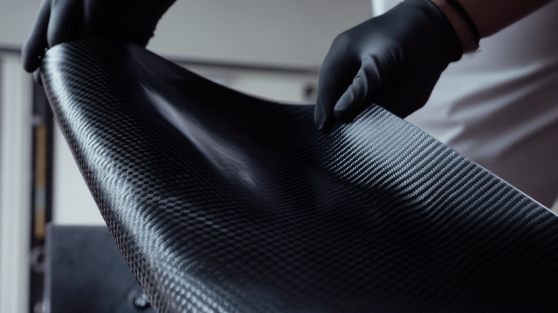

Carbon fiber is a very strong and lightweight material made from thin strands of

carbon.

These strands are used to create different things, like sports equipment, cars, and even parts of airplanes,

because carbon fiber is very strong but almost weightless.

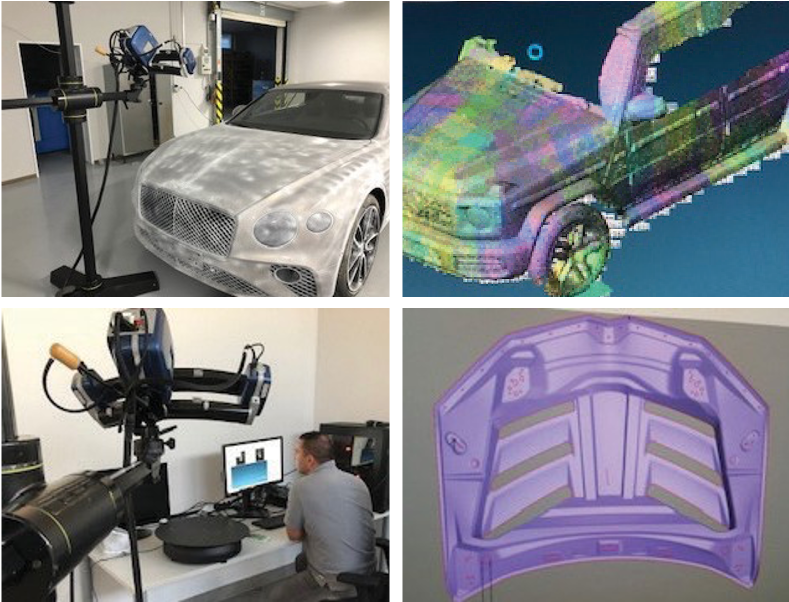

Our team works with a high-quality 3D scanner, which scans

the specific parts in extreme detail, processes this digital file, and then prepares it for the model-building

process.

Our expert scanning team uses

the fastest and most accurate 3D optical scanners available and will work closely with you to clearly understand

your needs set you up for success.

Positioning the data in the

preferred coordinate system. The processed model is then prepared for the modeling production stage.

This is one of the latest production processes in which primarily carbon fibers are processed. The precisely cut prepreg is placed and layered in a mold, then packed with other technical auxiliary films in a vacuum bag. The vacuum-stable unit is placed in an autoclave, where a highly acurate controlled program curing procedure is started by the application of heat and high pressure. The final result is a very strong, rigid, and lightweight product. This is one of the best processing and production of composite materials on the market. A method primarily used in the automotive, aerospace, motorsports, and healthcare industries.

At Satyar s.r.o., There is no project too small, too big, or too complex.

We supply exterior components for accessories and production, which includes diffusors, spoilers, bonnets, fender vents, hoods, mirror covers, etc. Components have perfectly aligned carbon- fiber and clear coated surface quality to enable long-term durability.

We supply carbon-fiber interior components with perfectly aligned fiber orientation and clear coated surface quality.

Our company Carbon Satyar s.r.o. is an industry leader in professional carbon production. We produce composite parts for which carbon, aramid, and glass fibers are processed using polyester, vinyl ester, and epoxy resins. With 22 years of experience in composites processing in the automotive industry, motorsports, aviation, medical technology, and agriculture, we have established ourselves as a reliable and soughtafter composites supplier for business partners worldwide. Our customers are from Germany, the Netherlands, Korea, England, and Dubai, along with many other countries around the globe. Stateof-the-art technologies have enabled us to provide our customers and partners with products of the highest quality. In addition, we are laser-focused on the requirements of our customers to create a lasting satisfied relationship through our products and services.

Innovation as a central driving force from technology to business processes, which are based on solid foundations of 20+ years of experience. Established local GM customer support for engineering, design, program management, supply and quality.

Czech Republic – low-cost country, skilled labor availability, established logistics system supporting NA market, geographically close to major European automotive customer.

Short development lead-times due to large in-house design, engineering and tooling manufacturing capacity as well as many outsource possibilities in nearby area